FOB Price

Get Latest Price2500 ~ 4200 / Set

|1 Set Minimum Order

Country:

China

Model No:

SL

FOB Price:

2500 ~ 4200 / Set Get Latest Price

Place of Origin:

qingdao

Price for Minimum Order:

2500 per Set

Minimum Order Quantity:

1 Set

Packaging Detail:

standdar wooden box

Delivery Time:

15-20days

Supplying Ability:

20 Set per Month

Payment Type:

T/T, L/C

Product Group :

Contact Person Hanny

Carson City, Nevada

Products Description

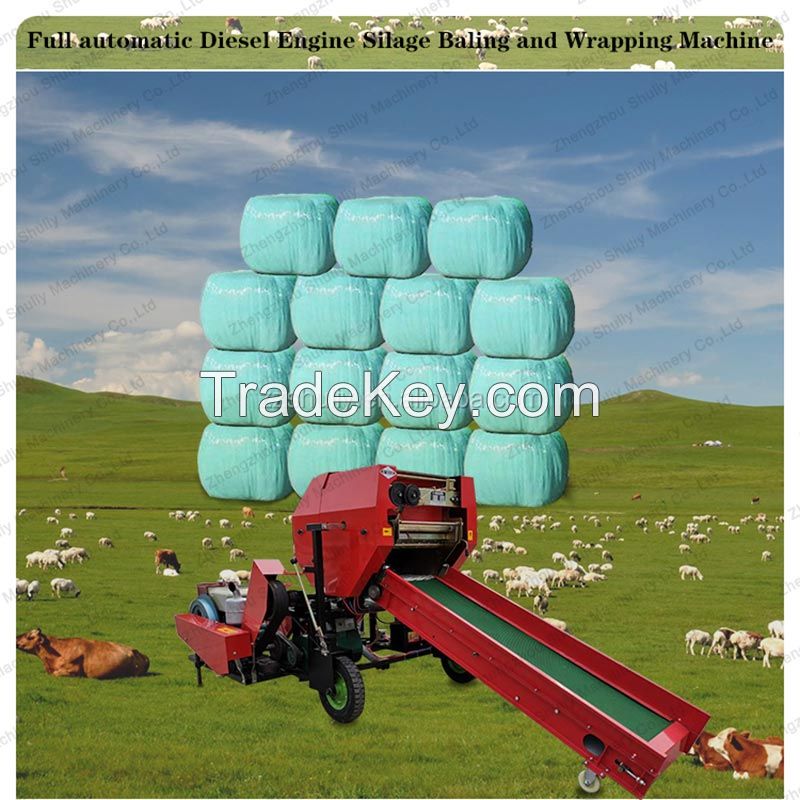

The silage baler and coating machine are a kind of advanced silage processing machine, which is suitable for the silage of corn stalks, sugarcane tail leaves, sweet potato vines, reeds, and bean vines. After adding water to the dry straw, it can be micronized after packaging with bacteria. It has a high commodity value, turns the discarded crops into treasures, improves the utilization rate of resources, makes up for the shortcomings of insufficient and low-quality forage sources in animal

husbandry, reduces the cost of feeding, and improves the Yield and

quality of meat or milk.

Products

Specification:

Products

Specification:

|

Model |

SL-55-52 |

|

Power |

5.5+1.1kw motor and 15hp diesel engine |

|

Bale size |

Φ550*520mm |

|

Baling speed |

50-60 pcs/h, 5-6t/h |

|

Machine size |

3520*1650*1650mm |

|

Machine weight |

850kg |

|

Bale weight |

65-100kg/bale |

|

Bale density |

450-500kg/m³ |

|

Film wrapping speed |

13s for 2 layer film ,19s for 3 layer film |

Through silage baler and coating machine, many parasites (such as

corn borer, and core borer) and harmful bacteria carried by raw

materials can also be eliminated. According to

measurements, on the same unit area of arable land, the

nutritional value of the whole

plant corn silage produced is 30% to 50% higher than the

nutritional value of the produced corn kernels plus dry corn

stalks.

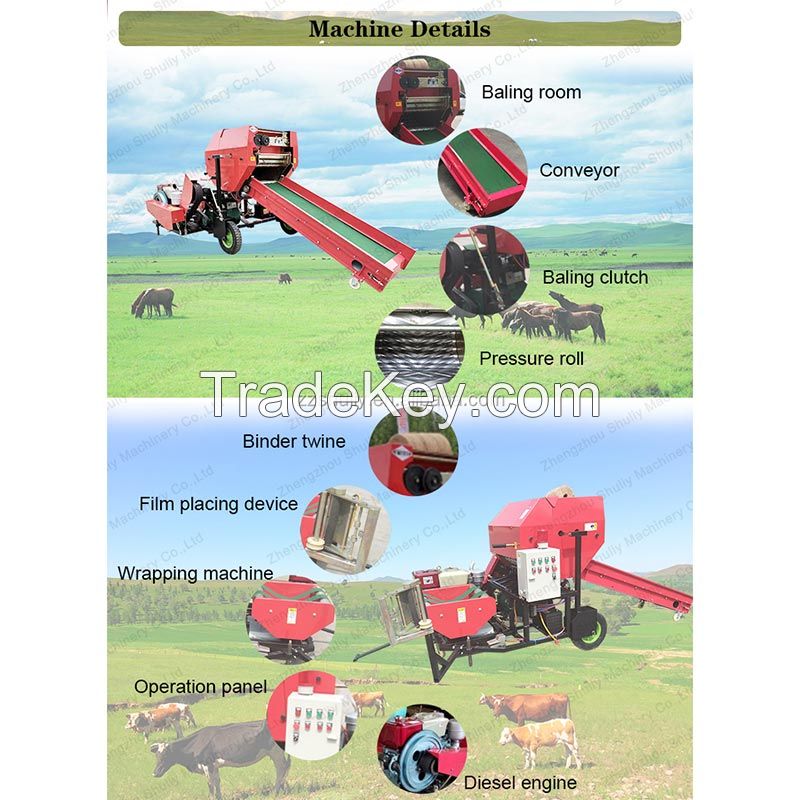

1. Copper core motor: to ensure the stable operation of the machine

and solve the compression problems of various

materials.

2. Fully automatic compression: Equipped with a fully automatic

microcomputer control distribution box, which can realize

automatic

feeding and compression

Packing and outpacing can effectively improve efficiency and save

labor costs.

3. Small conveyor belt design: anti-leakage material design,

labor-saving, one-person operation saves time and effort, and the

storage

time can reach 2-3 years.

4. Dual-purpose automatic netting/rope winding (net rope can be

switched freely according to demand)

5. Convenient maintenance: all the bearings of the whole machine

are external, which is convenient for maintenance and

maintenance

6. Automatic film leading and cutting, automatic film leading and

cutting, and coating (the number of coating layers can be

adjusted)

| Country: | China |

| Model No: | SL |

| FOB Price: | 2500 ~ 4200 / Set Get Latest Price |

| Place of Origin: | qingdao |

| Price for Minimum Order: | 2500 per Set |

| Minimum Order Quantity: | 1 Set |

| Packaging Detail: | standdar wooden box |

| Delivery Time: | 15-20days |

| Supplying Ability: | 20 Set per Month |

| Payment Type: | T/T, L/C |

| Product Group : | Agricultural Machine |