FOB Price

Get Latest Price( Negotiable )

|Minimum Order

Place of Origin:

-

Price for Minimum Order:

-

Minimum Order Quantity:

1 Set

Packaging Detail:

Large part is non-packed, small part is in wood case.

Delivery Time:

10-30 days

Supplying Ability:

1000 Unit per Month

Payment Type:

L/C, T/T

Algeria

Contact Person Mr. Brahim

Economical Zone, Ghardaia, Other

Working Principle:

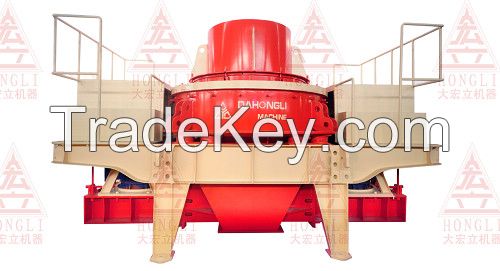

The 6HL-series High Efficiency Vertical Shaft Impact Crusher uses

the cascade feed system to introduce a second stream of material in

a controlled quantity into the crushing chamber turbulence, causing

a supercharging of the particle population within the chamber,

thereby improving the energy transfer between the particles. The

rocks that enter the crushing chamber collide violently with the

liners and move upward along the piling surface and then be crushed

against the rocks spurted out by the impeller, loose energy and

discharge from the crushing chamber. Cascade feed system offers

external hydraulic adjustment of the cascade ratio while the

crusher is operating to control the product specification and

grading accurately. Adjustment can be hand operated or be fully

integrated automated plant system. So it can adapt the changes of

the feed specification and totally control the product quality and

fines content.

Product Characteristics:

1. The 6HL hydraulic opening cover installation is convenient for enter the inner side during the machines maintenance.

2. The 6HL series High Efficiency Vertical Shaft Impact Crusher can control the product class of the product by optimizing various variables, such as using rotors of different diameter and different cyclic crushing chambers, changing the speed of the rotor, adjusting the stream of material.

3. Due to the low maintenance request and easy operation, the 6HL can conveniently match with the already existed and planning crushing equipment.

4. Simple and easy installation. The 6HL crusher only needs little structure support; its ideal mobile equipment.

5. By controlling the product class, it can get the maximum capacity and the minimum capacity.

6. It can produce high level cubic product.

7. It can raise the recycle rate of mineral with excellent monomer crushing characteristic.

8. Selective crushing function.

9. Several models are available for any combinations even the fourth crushing.

Technical Parameters:

|

Model specification |

6HL8522 |

6HL9532 |

6HL1145 |

||||||

|

Handling capacity(t/h) |

Flash fin Charge-in |

90-140 |

120-190 |

160-250 |

220-340 |

300-460 |

330-510 |

375-580 |

430-660 |

|

Central Charge-in |

70-120 |

95-155 |

125-205 |

170-270 |

230-350 |

255-395 |

290-450 |

330-510 |

|

|

Max. Feed capacity (mm) |

Soft material |

40 |

45 |

50 |

|||||

|

Hard material |

40 |

40 |

45 |

||||||

|

Installation power(KW) |

160 |

200 |

250 |

2×160 |

2×200 |

2×220 |

2×250 |

2×280 |

|

|

Driving collocation |

Single-motor |

Double-motor |

|||||||

|

Revolution speed(r/min) |

1200-1800 |

1100-1700 |

1000-1500 |

||||||

|

Whole-body weight(t) |

13 |

16.5 |

19 |

||||||

|

The output on the table will change with the variation of the operating parameters of the 6HL crusher. The output on the table is based on an average density of 1.6t/m3, and the feed and discharge is smooth and free of sticking and blocking. |

|||||||||

|

The central charge-in numbers in the form is calculated as bellow: lower limit=the speed of rotor line 75m/s (0% stream of material) upper limit= the speed of rotor line 60 m/s (0% stream of material) . |

|||||||||

|

The flash fin numbers in the form is calculated as bellow: lower limit=the speed of rotor line 75m/s(30% stream of material) upper limit= the speed of rotor line 60 m/s(100% stream of material) . |

|||||||||